TF 30K Servicing - How to.

For those of you who like to do their own work, here is how I carried out my 30k service.

There is a servicing sheet available on Tony Thompson's site, here http://www.apttony.co.uk/Servicing/ServiceSheets.html

First off all I checked the handbrake operation, lights, horn etc. All worked OK

I checked the screen and washers. One of the washer jets was loose and not spraying properly so I replaced it with a new one (£5), although the favoured replacements now are the Citroen Xsara ones which fit and give a better spray pattern. The jet just unclips from underneath and the new one pushes into place after swapping the gasket from the old one. You can set the jets up by jamming a pin or paperclip into the squirter hole and turning the jet to the required position.

Both the seatbelts, fixings etc were checked and found to be OK

Next I used some spray grease to lubricate the boot/bonnet and door hinges and catches. This is important if you want trouble free operation. Most people do this job when something has stopped operating correctly. This is called corrective maintenance rather than preventive maintenance and can be more problematic and expensive.

Door Catch

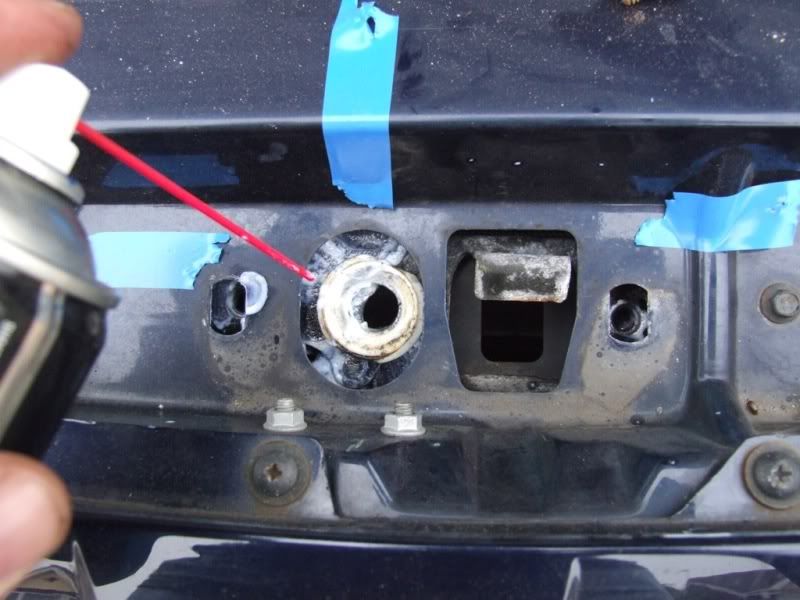

Boot Catch

Bonnet Catch

Lower bonnet catch. This is showing the lower catch with the top plate removed. The blue tape is there so that I can put the catch back together in the same place. This is worth doing as you could end up spending a fair bit of time setting the catch back up again. Give a good squirt of grease around inside left, as this is where the cable release from the boot operates the catch. If this seizes you can have a lot of problems getting in to your bonnet.

I also lubricated the bonnet hinges. Unfortunately the grease I am using is white and the hinges are visible with the bonnet closed. I therefore had to wipe some off.

The battery was checked and the terminals and chassis connection were greased to prevent corrosion.

Fluid levels were checked, although I am going to do a full brake fluid change when I fit the new rear brakes.

Next I moved to the engine bay.

To get full access you need to remove the engine inspection cover.

I checked all of the visible hoses for damage and all seemed OK

I haven't pressure checked the system as I haven't got the equipment to do it.

I did check the engine coolant was of a correct mixture and it checked out to -23 degrees using a hydrometer.

Next I changed the air filter for an itg freeflow panel filter.

The airbox is on the nearside of the engine bay

Here you can see the old and new filters for comparison

To do this you need to undo the jubilee clip holding the air box onto the induction manifold pipe and unclip the 4 clips that hold the top cover in place.

You now have to slide the airbox cover forward and through 90 degrees

and remove the cover

Then fit the new filter

Obviously the cover goes back on at this point, but I am replacing the fuel filter (Not part of the 30k service. Normally done at 60k or 4 years) while I am in and leaving the airbox cover off gives me a little more room.

The fuel filter is just to the left of the airbox. It is adviseable to pack kitchen roll around the connections as you undo them as fuel will escape. Take necessary precautions to avoid a fire and preferably do this with a cold engine.

First of all, disconnect the quick release coupling (Orange) at the top of the filter pipe. You do this by gripping the connector and pushing the black collar (Shown between my thumb and finger) in towards the connector. As you do this, pull the connector away from the pipe and it should pull straight off.

Next you need to use 2 spanners to undo the connection at the bottom of the filter. The bottom connection releases a lot of fuel when disconnected as the filter empties.

And pull the filter towards you out of the holder. The filter is held in by a clip at the neck of the holder. Just push this back and you can remove the filter

Here we have the new filter (the top pipe has already been removed and fitted to the new filter) and the old. One thing I noticed was that the old one is made of steel and the new one is ally. The new one feels a lot lighter.

Next comes the spark plug change. Again this is normally done at 60k or 4 years.

First remove the top cover from the engine. There are 3 bolts. Two long ones at the top and a shorter one in the middle front.

This exposes the coil packs and HT leads

Two of the plugs are easy to get at and you just pull the plug caps up and out.

The other two are accessed by removing the two 8mm securing bolts and pulling each coil pack up and out

It is best to do one plug at a time so that you do not mix up the leads.

The plugs are a long, long way down. You will need a proper spark plug socket and an extension bar to remove them

I have since discovered this magnetic plug tool which I bought from Halfords.

It could have been made for the K-series engine as it is just the right length and grips the plug securely. It is also very easy to hand position and tighten the plug so avoiding cross threading.

Before torquing to the correct value.

Here are the new plugs waiting to be fitted

Fit the new plugs, torque to the manufacturers recommended setting, and refit the covers, coil packs and cover.

Next comes the oil change

Take the car for a nice long drive until the engine is at working temperature. This will help the oil drain easier due to it being thinner.

WARNING. In the next steps the oil will be extremely hot and old oil is carcinogenic. For those of you who don't know, this means that it can cause cancer. So take appropriate precautions to avoid exposure to the engine oil.

Ensure the car is on level ground, place a suitable container under the sump and remove the sump plug. Also remove the filler cap (yellow) on the top of the engine. This will allow the oil to drain faster.

The sump plug is located at the bottom front offside of the engine

Allow all of the oil to drain from the sump.

Now refit the sump plug USING THE OLD WASHER.

Now fill up the engine with oil through the rocker cover filler. Only the best quality oil for me

Seriously though, the next step is optional. Fill the engine with a cheap oil of the correct viscosity and run the engine until it is at working temperature.

Switch off the engine and drain the oil again. This will flush the engine and help remove old oil and sludge. You can buy proper flushing oil with detergents that remove deposits etc, but some people think that the detergents may remove layers and sludge that is holding your engine together. You can be too clean.

Once the oil has drained, pour the remainder of the oil into the filler and watch the drain. Clear oil should start coming out.

Once drained, refit the sump plug WITH THE NEW WASHER.

Now jack the car up and either use an axle stand or place a substantial piece of wood that will take the weight of the car under the rear offside wheel. Lower the car onto the jack or wood.

NEVER work under a car with just the jack supporting it, it is dangerous and could collapse with you under it.

This will give you easier access to the oil filter, which is just above the sump plug.

Place a drip tray under the oil filter, remembering that the filter contains a substantial amount of hot, old engine oil.

Using a strap wrench, or filter removal tool, remove the oil filter.

Prepare the new oil filter by smearing a small amount of new engine oil around the rubber seal. This will aid sealing.

Fit the new filter hand tight and then an extra 3/4 of a turn.

Remove any axle stands, jacks etc so that the car is level and fill the engine with new oil. This is the real stuff

Once the engine is filled to the correct level start the engine and let it run for a few minutes. This allows the empty oil filter and engine to fill. Switch off the engine, leave for 5 mins and top up the oil, checking the level on the dipstick

At this point you should check your wheel bearings, drive shafts, gaiters, remove wheels and check tyre tread depths etc, check brake pad wear. I have been doing this while I have been replacing the discs and pads. See other threads. When checking pads be sure to check ALL pads as the inner pads tend to wear faster than the outer pads on some brakes.

Check under the car and around the engine bay for evidence of fuel, oil or any other fluid leaks. Also check your suspension and steering components for signs of damage and leaks.

Examine you exhaust and heat shield for deterioration.

The brake fluid should be changed at 30k or 2 years but I will be doing this once I have replaced my rear brakes.

Now refit the engine inspection hatch and associated components.

Check your tyre pressures.

Lastly, you should carry out a corrosion check. You may have noticed on some of the oil change pics that the rear subframe had a fair bit of surface corrosion. I have now covered this using a spraycan of Waxoil which should sort that out.

That is the servicing completed

One thing that isn't mentioned on the servicing sheet is the suspension grease points. You will need a grease gun for this and some general purpose LM grease. Push the gun onto the grease nipple and inject a few squirts of grease (I did 5 on each). There are only the 2 grease nipples on the TF, one on each front upper arm.

I hope this helps people. The usual disclaimers apply etc

There is a servicing sheet available on Tony Thompson's site, here http://www.apttony.co.uk/Servicing/ServiceSheets.html

First off all I checked the handbrake operation, lights, horn etc. All worked OK

I checked the screen and washers. One of the washer jets was loose and not spraying properly so I replaced it with a new one (£5), although the favoured replacements now are the Citroen Xsara ones which fit and give a better spray pattern. The jet just unclips from underneath and the new one pushes into place after swapping the gasket from the old one. You can set the jets up by jamming a pin or paperclip into the squirter hole and turning the jet to the required position.

Both the seatbelts, fixings etc were checked and found to be OK

Next I used some spray grease to lubricate the boot/bonnet and door hinges and catches. This is important if you want trouble free operation. Most people do this job when something has stopped operating correctly. This is called corrective maintenance rather than preventive maintenance and can be more problematic and expensive.

Door Catch

Boot Catch

Bonnet Catch

Lower bonnet catch. This is showing the lower catch with the top plate removed. The blue tape is there so that I can put the catch back together in the same place. This is worth doing as you could end up spending a fair bit of time setting the catch back up again. Give a good squirt of grease around inside left, as this is where the cable release from the boot operates the catch. If this seizes you can have a lot of problems getting in to your bonnet.

I also lubricated the bonnet hinges. Unfortunately the grease I am using is white and the hinges are visible with the bonnet closed. I therefore had to wipe some off.

The battery was checked and the terminals and chassis connection were greased to prevent corrosion.

Fluid levels were checked, although I am going to do a full brake fluid change when I fit the new rear brakes.

Next I moved to the engine bay.

To get full access you need to remove the engine inspection cover.

I checked all of the visible hoses for damage and all seemed OK

I haven't pressure checked the system as I haven't got the equipment to do it.

I did check the engine coolant was of a correct mixture and it checked out to -23 degrees using a hydrometer.

Next I changed the air filter for an itg freeflow panel filter.

The airbox is on the nearside of the engine bay

Here you can see the old and new filters for comparison

To do this you need to undo the jubilee clip holding the air box onto the induction manifold pipe and unclip the 4 clips that hold the top cover in place.

You now have to slide the airbox cover forward and through 90 degrees

and remove the cover

Then fit the new filter

Obviously the cover goes back on at this point, but I am replacing the fuel filter (Not part of the 30k service. Normally done at 60k or 4 years) while I am in and leaving the airbox cover off gives me a little more room.

The fuel filter is just to the left of the airbox. It is adviseable to pack kitchen roll around the connections as you undo them as fuel will escape. Take necessary precautions to avoid a fire and preferably do this with a cold engine.

First of all, disconnect the quick release coupling (Orange) at the top of the filter pipe. You do this by gripping the connector and pushing the black collar (Shown between my thumb and finger) in towards the connector. As you do this, pull the connector away from the pipe and it should pull straight off.

Next you need to use 2 spanners to undo the connection at the bottom of the filter. The bottom connection releases a lot of fuel when disconnected as the filter empties.

And pull the filter towards you out of the holder. The filter is held in by a clip at the neck of the holder. Just push this back and you can remove the filter

Here we have the new filter (the top pipe has already been removed and fitted to the new filter) and the old. One thing I noticed was that the old one is made of steel and the new one is ally. The new one feels a lot lighter.

Next comes the spark plug change. Again this is normally done at 60k or 4 years.

First remove the top cover from the engine. There are 3 bolts. Two long ones at the top and a shorter one in the middle front.

This exposes the coil packs and HT leads

Two of the plugs are easy to get at and you just pull the plug caps up and out.

The other two are accessed by removing the two 8mm securing bolts and pulling each coil pack up and out

It is best to do one plug at a time so that you do not mix up the leads.

The plugs are a long, long way down. You will need a proper spark plug socket and an extension bar to remove them

I have since discovered this magnetic plug tool which I bought from Halfords.

It could have been made for the K-series engine as it is just the right length and grips the plug securely. It is also very easy to hand position and tighten the plug so avoiding cross threading.

Before torquing to the correct value.

Here are the new plugs waiting to be fitted

Fit the new plugs, torque to the manufacturers recommended setting, and refit the covers, coil packs and cover.

Next comes the oil change

Take the car for a nice long drive until the engine is at working temperature. This will help the oil drain easier due to it being thinner.

WARNING. In the next steps the oil will be extremely hot and old oil is carcinogenic. For those of you who don't know, this means that it can cause cancer. So take appropriate precautions to avoid exposure to the engine oil.

Ensure the car is on level ground, place a suitable container under the sump and remove the sump plug. Also remove the filler cap (yellow) on the top of the engine. This will allow the oil to drain faster.

The sump plug is located at the bottom front offside of the engine

Allow all of the oil to drain from the sump.

Now refit the sump plug USING THE OLD WASHER.

Now fill up the engine with oil through the rocker cover filler. Only the best quality oil for me

Seriously though, the next step is optional. Fill the engine with a cheap oil of the correct viscosity and run the engine until it is at working temperature.

Switch off the engine and drain the oil again. This will flush the engine and help remove old oil and sludge. You can buy proper flushing oil with detergents that remove deposits etc, but some people think that the detergents may remove layers and sludge that is holding your engine together. You can be too clean.

Once the oil has drained, pour the remainder of the oil into the filler and watch the drain. Clear oil should start coming out.

Once drained, refit the sump plug WITH THE NEW WASHER.

Now jack the car up and either use an axle stand or place a substantial piece of wood that will take the weight of the car under the rear offside wheel. Lower the car onto the jack or wood.

NEVER work under a car with just the jack supporting it, it is dangerous and could collapse with you under it.

This will give you easier access to the oil filter, which is just above the sump plug.

Place a drip tray under the oil filter, remembering that the filter contains a substantial amount of hot, old engine oil.

Using a strap wrench, or filter removal tool, remove the oil filter.

Prepare the new oil filter by smearing a small amount of new engine oil around the rubber seal. This will aid sealing.

Fit the new filter hand tight and then an extra 3/4 of a turn.

Remove any axle stands, jacks etc so that the car is level and fill the engine with new oil. This is the real stuff

Once the engine is filled to the correct level start the engine and let it run for a few minutes. This allows the empty oil filter and engine to fill. Switch off the engine, leave for 5 mins and top up the oil, checking the level on the dipstick

At this point you should check your wheel bearings, drive shafts, gaiters, remove wheels and check tyre tread depths etc, check brake pad wear. I have been doing this while I have been replacing the discs and pads. See other threads. When checking pads be sure to check ALL pads as the inner pads tend to wear faster than the outer pads on some brakes.

Check under the car and around the engine bay for evidence of fuel, oil or any other fluid leaks. Also check your suspension and steering components for signs of damage and leaks.

Examine you exhaust and heat shield for deterioration.

The brake fluid should be changed at 30k or 2 years but I will be doing this once I have replaced my rear brakes.

Now refit the engine inspection hatch and associated components.

Check your tyre pressures.

Lastly, you should carry out a corrosion check. You may have noticed on some of the oil change pics that the rear subframe had a fair bit of surface corrosion. I have now covered this using a spraycan of Waxoil which should sort that out.

That is the servicing completed

One thing that isn't mentioned on the servicing sheet is the suspension grease points. You will need a grease gun for this and some general purpose LM grease. Push the gun onto the grease nipple and inject a few squirts of grease (I did 5 on each). There are only the 2 grease nipples on the TF, one on each front upper arm.

I hope this helps people. The usual disclaimers apply etc

Last Edit:11 years 1 month ago

by cjj

Last edit: 11 years 1 month ago by cjj.

The following user(s) said Thank You: cairnsys

Please Log in or Create an account to join the conversation.

Hi cjj

you only fond 2 grease nipples as there is only 2 on a TF

I would put the car on ramps to change oil as it would help the oil flow out better

you only fond 2 grease nipples as there is only 2 on a TF

I would put the car on ramps to change oil as it would help the oil flow out better

BILSTIEN DAMPERS, 4-2-1 MANIFOLD, HEAD WORK BY SABRE.

by helsbyman

Please Log in or Create an account to join the conversation.

- Leigh Ping

-

Offline

Offline

- Moderator

-

- Posts: 6838

- Thanks: 1631

helsbyman wrote: Hi cjj

you only fond 2 grease nipples as there is only 2 on a TF

I would put the car on ramps to change oil as it would help the oil flow out better

Ha, yeah I know.

It is an old post that I thought I had converted for this site. It was only when I was trying to find it that I realised I hadn't.

I prefer to keep the car fairly level when draining the oil.

by cjj

Please Log in or Create an account to join the conversation.

Nice one. I might have a go at this sometime when I have some time.

by bensewell

Please Log in or Create an account to join the conversation.

I have used this guide and found it very useful. Thanks CJJ. I was aware that the F had 2 extra grease nipples in the same place but on the rear so didn't miss them.

[IMG]ht[/img]

by Davem

Please Log in or Create an account to join the conversation.

- adamelphick

-

Offline

Offline

- Moderator

-

- Posts: 3162

- Thanks: 572

Great Guide.

I also always use cheapo oil in the moddle of the flush to get out the last remnants of crap... works a treat. I've done the same for years on my Rangie and at almost 170K he's still sweet as a nut!

I also always use cheapo oil in the moddle of the flush to get out the last remnants of crap... works a treat. I've done the same for years on my Rangie and at almost 170K he's still sweet as a nut!

by adamelphick

Please Log in or Create an account to join the conversation.

Time to create page: 0.575 seconds