exhaust manifold studs

Just a quick one...

Im goin to be changing my down pipe the weekend to a stainless steel part

Are the studs/bolts that hold the manifold to the down pipe captive or do u need a spanner on the top and rachet from underneith??

Do i need to access the engine bay or can it be swopped from just underneith the car??

Anything to be wary off or any tricks or tips that anyone can share before i take on the challenge??

Im goin to be changing my down pipe the weekend to a stainless steel part

Are the studs/bolts that hold the manifold to the down pipe captive or do u need a spanner on the top and rachet from underneith??

Do i need to access the engine bay or can it be swopped from just underneith the car??

Anything to be wary off or any tricks or tips that anyone can share before i take on the challenge??

by CR41G

Please Log in or Create an account to join the conversation.

Just need a long bar / ratchet with a 15mm deep drive on it. Put goggles on too my eyes nearly bled when I did mine with the amount of grit and crud that came out.

by bensewell

The following user(s) said Thank You: Leigh Ping

Please Log in or Create an account to join the conversation.

You'll need to take the engine bay off to feed the lambda sensor from the downpipe backup through the engine bay and back into the right connector. You'll need a 19mm or 21mm spanner for that I used a deep socket with a slit in it.

Adopt the position of a upside down cockroach for an hour and you'll be fine lol.

Another tip...

As the old downpipe might be on the original nuts where ita connected to the catalytic converter you will have great fun trying to get them off. I cut the downpipe off with a grinder then attacked the cat easier to grind the nuts off.

Get some stainless steel 'cat saver' nuts.

Adopt the position of a upside down cockroach for an hour and you'll be fine lol.

Another tip...

As the old downpipe might be on the original nuts where ita connected to the catalytic converter you will have great fun trying to get them off. I cut the downpipe off with a grinder then attacked the cat easier to grind the nuts off.

Get some stainless steel 'cat saver' nuts.

by bensewell

The following user(s) said Thank You: Leigh Ping

Please Log in or Create an account to join the conversation.

Ive got a half drive rachet set with extension bars but i dont have deep sockets ermm is it definatly a 15mm deep socket thats needed ?? Or will a standard 15mm socket do the job??

Just asking so i can go and buy one if its 100% needed

Thanks for your reply

Just asking so i can go and buy one if its 100% needed

Thanks for your reply

by CR41G

Please Log in or Create an account to join the conversation.

A standard will do but I found the extra grip on the deep drive made it a bit easier as it a awkard angle to get at.

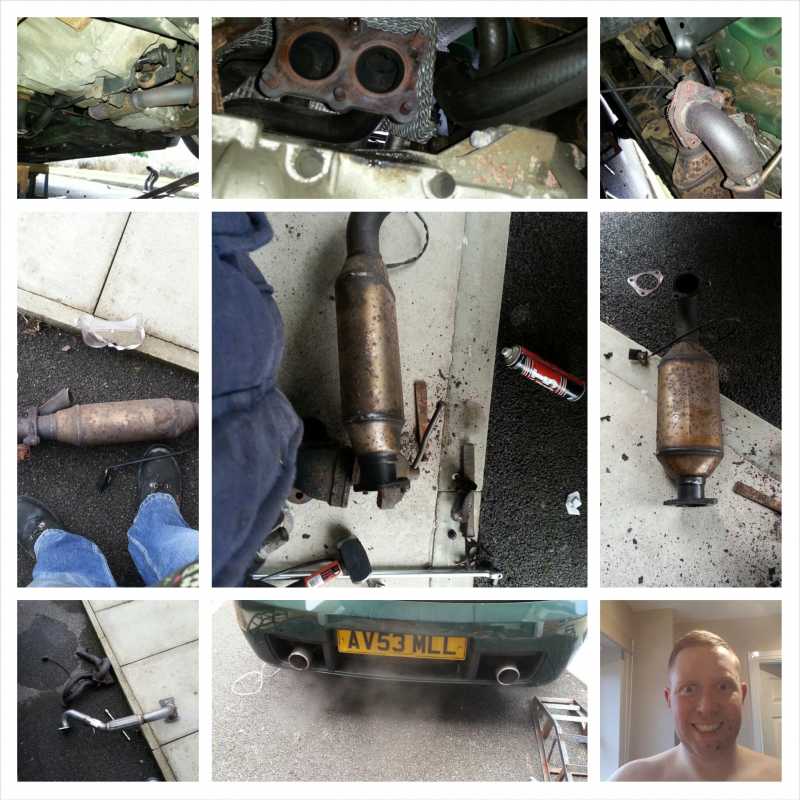

Here's a nice collage of what your faced with:

Also make sure you get the back end of the car high up as there's not a lot of room to manovere. Less swearing and blood loss will occur with the car higher in the air

Here's a nice collage of what your faced with:

Also make sure you get the back end of the car high up as there's not a lot of room to manovere. Less swearing and blood loss will occur with the car higher in the air

Last Edit:10 years 1 month ago

by bensewell

Last edit: 10 years 1 month ago by bensewell.

Please Log in or Create an account to join the conversation.

Funnily enough, hoping to do the same job myself this weekend. Got a couple of quick questions for you Ben.

Did you find there was enough room with the car just on ramps, or did you try and raise the front of the car a bit as well? And, did you use any exhaust paste on any of the couplers/gaskets?

I have also read elswhere that it is a good idea to use stainless bolts and split washers and copper nuts, as this makes it easier to remove said fixings later on for removing cat etc. Has anyone got experience of using these, as I am a bit concerned about overtightening and stripping the thread on the nuts. Torque settings for example?

Did you find there was enough room with the car just on ramps, or did you try and raise the front of the car a bit as well? And, did you use any exhaust paste on any of the couplers/gaskets?

I have also read elswhere that it is a good idea to use stainless bolts and split washers and copper nuts, as this makes it easier to remove said fixings later on for removing cat etc. Has anyone got experience of using these, as I am a bit concerned about overtightening and stripping the thread on the nuts. Torque settings for example?

Last Edit:10 years 1 month ago

by Billy

Last edit: 10 years 1 month ago by Billy.

Please Log in or Create an account to join the conversation.

Ignore the bit about the paste, just read about it on the other thread about the s/s exhaust. Still interested about the fixings though.

by Billy

Please Log in or Create an account to join the conversation.

Don't bother with paste. I did mine on the drive with some low profile ramps to start with to get the car in the air. Then jacked the car a bit higher with some axle stands and chocks.

Get some stainless nuts if you can they are brill.

This is what I got:

MG TF Catalytic Converter CAT Fitting Kit Gaskets Bolts Deep Nuts

Get some stainless nuts if you can they are brill.

This is what I got:

by bensewell

Please Log in or Create an account to join the conversation.

Ta for that.

by Billy

The following user(s) said Thank You: bensewell

Please Log in or Create an account to join the conversation.

I did my backbox by using a small axel tand on the nearside only ... It was a squeeze but i managed it .

On this job the cars goin up on ramps.

Im not using paste either just the all new gaskets that were suplied with the pipe

On this job the cars goin up on ramps.

Im not using paste either just the all new gaskets that were suplied with the pipe

by CR41G

Please Log in or Create an account to join the conversation.

- bryan young

-

Offline

Offline

- Master MGer

-

- Posts: 3631

- Thanks: 773

Don't use paste before the cat as it can break off and damage the cat. use stainless cat saver nuts, proper gaskets and torque up correctly. i replaced my manifold studs with stainless from Volksbolts (they have a hexagon socket in the end so very easy to install, copper slip the threads because going into alloy. :clap:

by bryan young

Please Log in or Create an account to join the conversation.