How to fit an OEM wind stop

Please note the design changed slightly on the Chinese models but both types fit in the same way.

Take your time with the first stage it is very important to get the holes in the correct position.

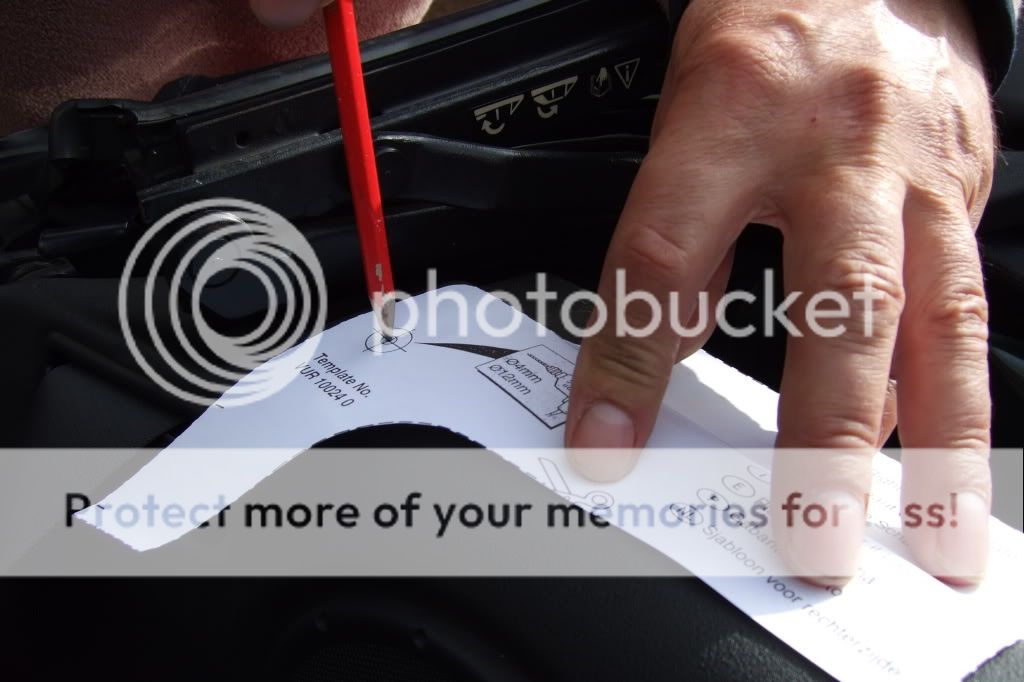

First carefully cut out and fix in place the hole template provided with the wind stop.

Mark out the position for the access/fitting holes to be drilled

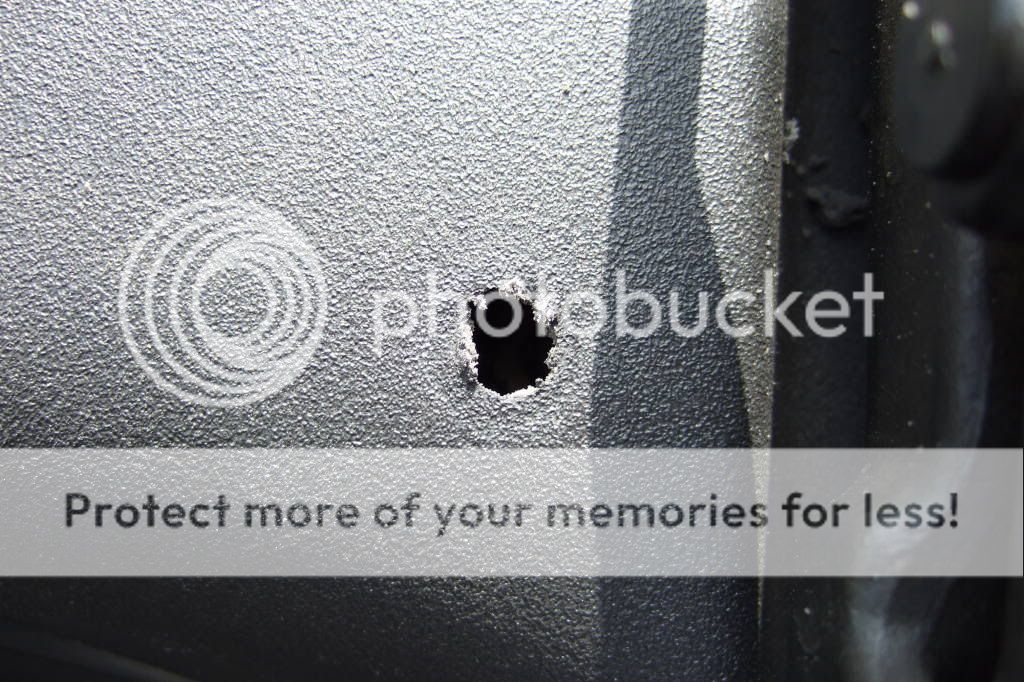

Please note the arrowed hole is from a fixed wind stop I had removed and has nothing to do with the fitting of an OEM wind stop.

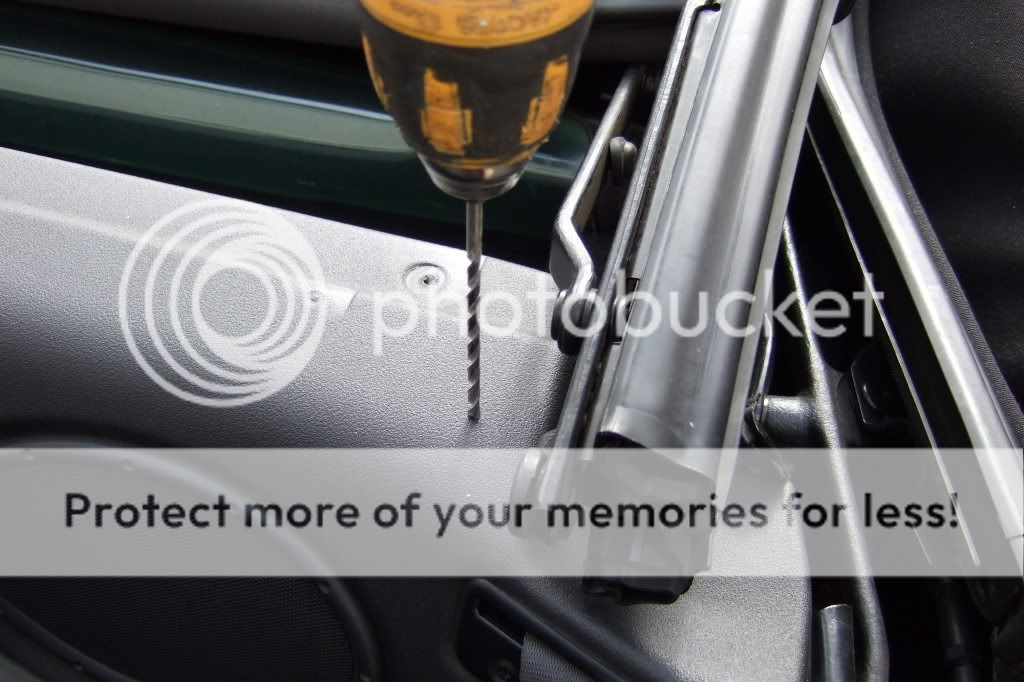

Starting with a thin bit, drill a hole in the marked position.

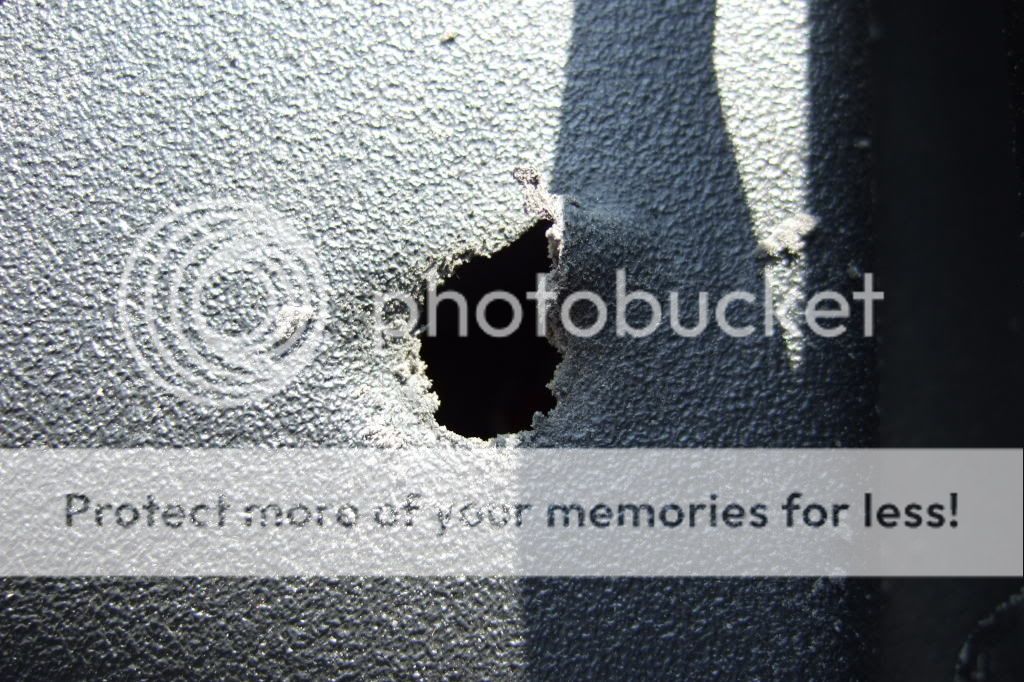

Enlarge hole to allow access to the 10mm (not 8mm has the instructin shet says) bolt.

The hole center is...

Yellow line 4cm

Red line 2 cm

Please Log in or Create an account to join the conversation.

Please note the arrowed hole is from a fixed wind stop that I had removed and has nothing to do with fitting an OEM wind stop.

Repeat for other side. Once both bolts are removed you can line up the wind stop retaining support brackets. This is just a case of aligning them with the drilled holes. The allen bolt goes through the hole in the bracket, lift the bracket slightly and put the allen bolt through the plastic dowel provided in the fitting kit. A small piece of Blue Tak or Cellotape will prevent the dowel coming away from the allen bolt and falling into the hole has you position it.

Once again repeat for other side

Please Log in or Create an account to join the conversation.

Place wind stop into retaining brackets.............

...and fit the wing nuts

Finally tighten wing nuts and ensure wind stop lowers and lifts properly.

Please Log in or Create an account to join the conversation.

i thought you had done this on your 85 then saw the red paint

mad about cars and bikes ![]()

if it aint broke dont fix it ![]()

Please Log in or Create an account to join the conversation.

MGF MARK wrote: hi John

i thought you had done this on your 85 then saw the red paint

No matey the 85 comes with a wind stop has standard. This one was added to my F.

This picture shows the wind stop my F came with when I bought her...............

Please Log in or Create an account to join the conversation.

Why do I need the paper templates ? I understand the scope of templates is to drill the 12mm holes directly on the top of the heads of the M8 bolts in order to be able to loose and take out the M8 bolts without removing the main rear bulkhead finisher.

But in order to make a better job why not remove the bulkhead, loose the M8 bolts without removing them, then pressing down the bulkead in order to mark/stamp the hex bolt heads shape in the plastic, this should provide a more precise reference for drilling. Ok it's longer but you are sure to match the position on the bolts and carry out two more precise holes.

Thanks for you advice.

Please Log in or Create an account to join the conversation.

if you do this you will bend the plastic out of shape meaning the impression will then be in the wrong place :slapme:

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Enndee1963

-

Offline

Offline

- Novice MGer

-

- Posts: 2

- Thanks: 0

Please Log in or Create an account to join the conversation.

Mike

Please Log in or Create an account to join the conversation.